A Little Knowledge About 430 Stainless Steel

The Japanese standard 430 stainless steel is the source of its name. It is very corrosion resistant. It is a general purpose steel similar to 304 stainless, but is ferritic. Its thermal conductivity and thermal expansion coefficient are lower than austenitic. It also has excellent mechanical properties and thermal fatigue resistance in the welding area. Because 430 stainless is cheaper than 304 stainless, it can be used to replace it in many ways.

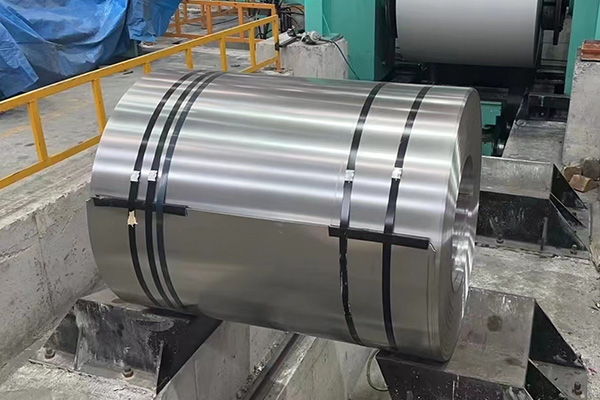

430 stainless Steel Coil

The chemical composition for 430 stainless steel is: carbon element S0.12%; silicon element =0.75%; manganese element 1.0%; phosphorus element 0.40 percent and sulfur element 0.30 percent.

The element content of nickel is between 0.60% and chromium is between 16.00-18.00%.

Surface grades of 430 stainless have the following states. The corrosion resistance of stainless steel 430 is different depending on the surface state. Common surface states include NO.1, 1D, 2D, 2B, N0.4, HL, BA, etc.

Let's discuss the processing technologies of different surfaces of 430 stainless. We'll start with the 1D surface. The surface is matte and has a granular discontinuity. Hot rolling, annealing, shot peening, and pickling are the steps in the processing sequence. Cold rolling, annealing, and pickling follow.

The 2D surface is a silvery-white with a slight gloss. The corresponding processing methods are hot rolling, annealing, shot peening, and pickling; cold rolling, and annealing, pickling, and tempering. The 2B surface is a silvery-white with a better gloss, flatness and processing. It can be hot, annealed pickled or cold, annealed pickled and temper. BA has a very high reflectivity and a very high surface gloss. It is similar to mirrored surfaces. Hot rolling, Annealing, Shot peening, and Pickling are the processing technologies. Cold rolling, annealing, and Pickling is followed by surface polishing, and tempering.

No.3's surface has a good gloss, but a rough texture. The processing technique is to use 100 - 120 abrasive material for polishing or tempering 2D or 2B products.

No.4 is a relatively glossy surface with fine lines. For 2D or 2B products, the corresponding processing technique is to use 150-180 materials of abrasive grit for polishing and tempering.

The uses of 430 stainless are numerous. It is used primarily to manufacture electronic products, tables, bolts and nuts, screens etc. It can be turned into decorative materials, outdoor advertising columns and products that require stress corrosion resistance. Parts for building decoration, fuel burners, household appliances, and home appliance parts. Due to its excellent corrosion resistance, 430 stainless can be used for chemical equipment that produces nitric acids.

Name: Acewell Metail

phone:86-18158892901

Whatsapp:8618158892901

Email:[email protected]

Add:NO.18 Huaye Avenue, Zhenyang Industrial Park