316 Stainless Steel vs Duplex 2205 Stainless Steel

316 Stainless Steel vs Duplex 2205 Stainless Steel

Both 316 and 2205 are very common stainless steel on the market. What's the difference? How to choose? Let's look at the two materials and see which is best for you.

316 Stainless steel

The austenitic stainless steel grade 316 (also known as 1.4401 or 1.4435 in the case of 316L) is composed of 16%-18% chrome, 10%-14% Nickel and 2%-3% molybdenum. The high corrosion resistance of this grade of stainless steel and its excellent formability make it one of the most widely used grades. The 316 stainless is widely used in the chemical processing industry, marine environment equipment, pharmaceutical equipment food processing equipment medical equipment as well as other fields that require excellent corrosion resistance.

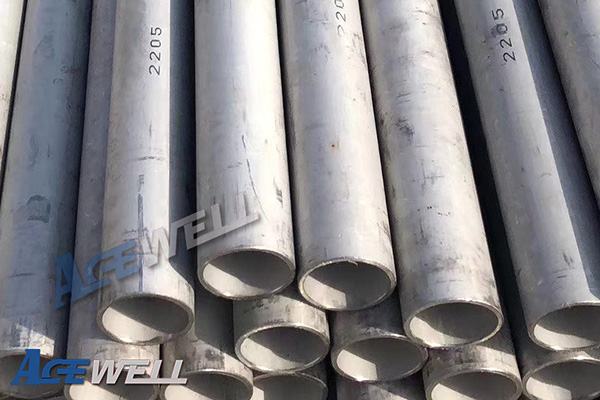

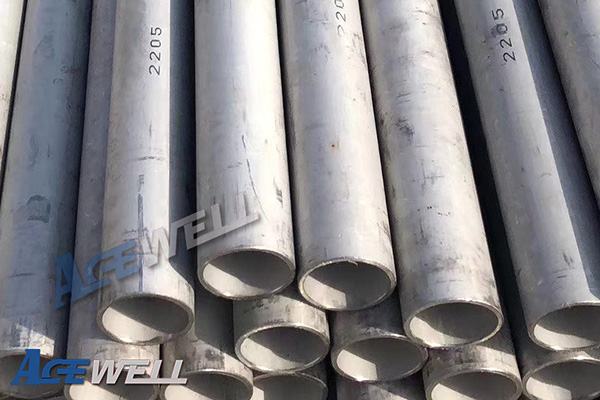

2205 Duplex Stainless Steel

The Grade 2205 Stainless Steel, also called S31803 and 1.4462 is a duplex stainless alloy composed of 21% chrome, 2.5% Molybdenum, and 4.5% Nickel-Nitrogen alloy. It is a Duplex Stainless Steel with high strength and impact toughness, and good local and overall resistance to stress corrosion. Solid solution is composed of half ferrite, half austenite. The minimum phase content should be 30%. 2205 stainless steel can be used for pressure vessels, high pressure storage tanks, high pressure pipelines and heat exchangers. It is also widely used in sewage treatment, pulp and paper industry, bleaching equipment and storage and treatment systems.

Differences between SS 2205 and SS 316

Chemical Composition

The grade 2205 contains more chromium and manganese, as well as nitrogen, than the grade 316. It is stronger than 316 SS but more prone for corrosion. Grade 316 SS, on the other hand, has higher levels of nickel and molybdenum which give it superior corrosion resistance to 2205 SS.

Physical Components

Duplex 2205 has a yield strength that is 1 time greater than 316L and it can be molded with ease. Duplex 2205 pressure vessels have a wall thickness that is 30-50% less than 316L. This can reduce the cost.

Duplex 2205 is excellent at resisting stress corrosion, particularly when used in marine environments containing chloride. Stress corrosion is a major problem for austenitic steels, including 316L.

Duplex 2205 has a linear expansion coefficient that is less than 316L and is closer to carbon steel. Duplex 2205 is therefore suitable for carbon steel connections, which has a significant impact on engineering.

Duplex 2205 is a better material for structural components or pipes in the event of an emergency such as an explosion or impact.

The lower nickel and molybdenum content of grade 2205 makes it easier to fusion weld, with less risk of cracks forming.

Cost Difference between Duplex 2205 and 316 Stainless Steel

In general, 2205 is about 20% more expensive than 316. Please contact us if you have any further questions.